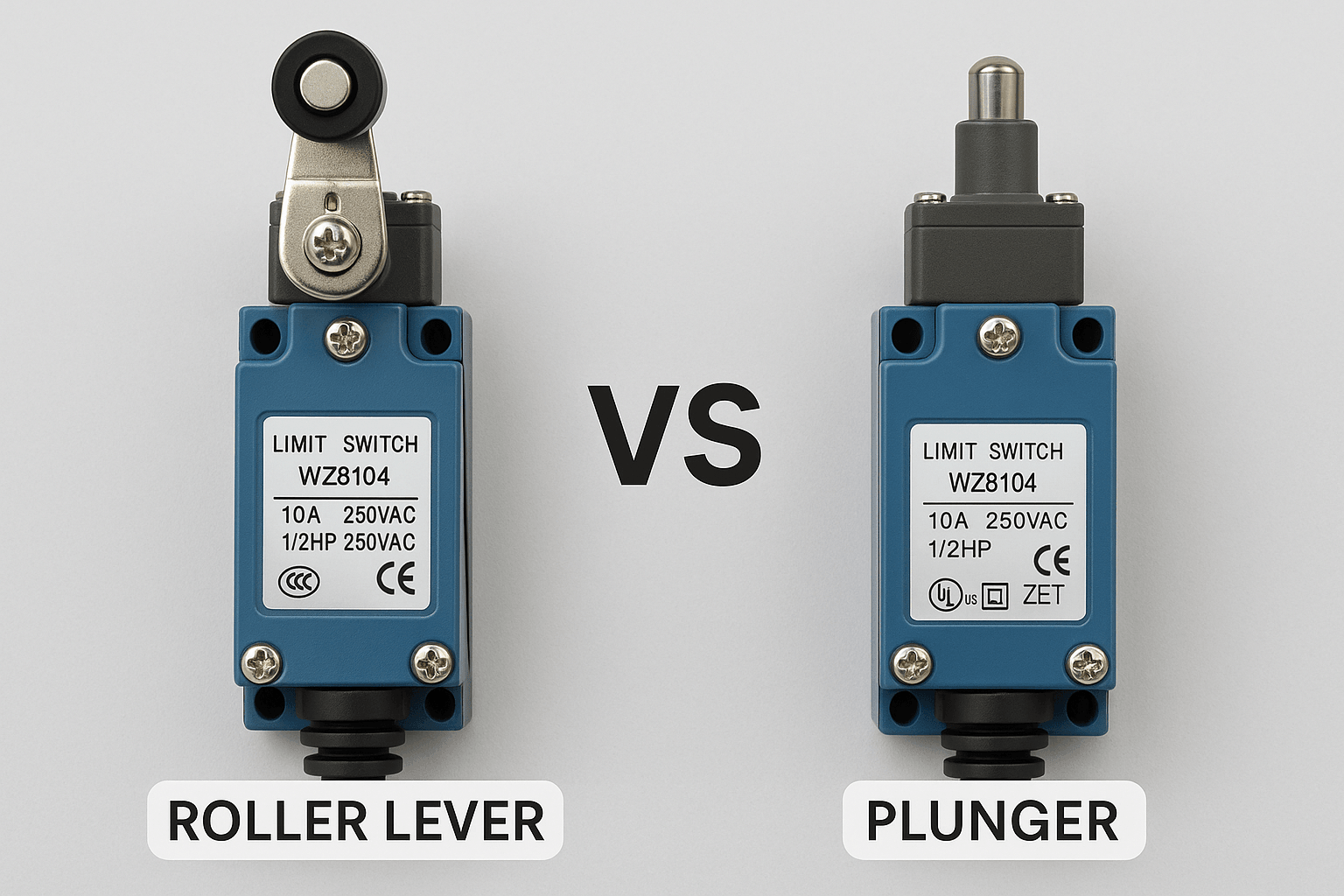

Limit switches come with different actuator styles, each suited to specific tasks. A roller lever limit switch has a rotating lever arm tipped with a roller, while a plunger limit switch has a straight, push-button actuator. Roller levers are great when the actuating force might hit at an angle or come from the side: the roller reduces friction and required force. Plunger switches are activated by a direct perpendicular push on the end of the actuator.

Roller Lever Limit Switch

A roller lever switch uses a pivoting lever arm. The lever can be fixed-length or adjustable, and it usually ends in a roller wheel. Because the roller absorbs some of the friction, this design requires less force to activate than a blunt plunger. They work well when the travel path is limited in height, or when slight misalignment may occur.

Plunger Limit Switch

Plunger limit switches have a straight actuating shaft (the plunger) that moves in and out. These switches are triggered by a direct push on the plunger tip. They are simple and robust. Since the plunger only moves linearly, no rotation of a lever is needed. Because the force is applied directly at 90°, plunger switches can be very precise in the point of activation.

Choosing Between Roller and Plunger:

- Actuation Direction

- Force Required

- Space Constraints

- Reset Behavior

- Typical Uses

In summary, use a roller lever switch when your trigger force may be angled or needs low activation force, and use a plunger switch for straightforward, linear stops. Choosing the right actuator will improve reliability.

Roller Lever vs Plunger Limit Switch: Which Is Best?